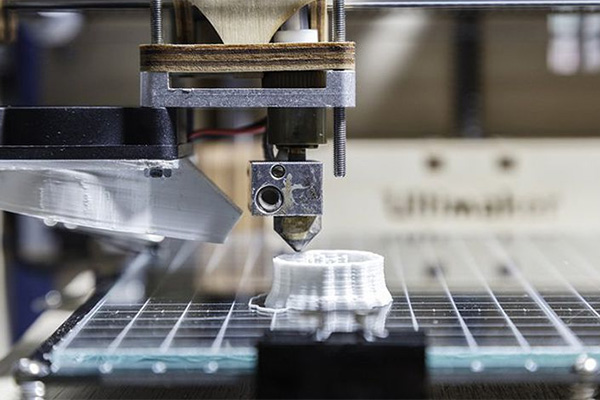

“Researchers from Poland’s Silesian University of Technology are getting in on the recycling action via 3D printing, and the title of their recently published paper certainly grabs the attention, whether you are a tech buff or not. ‘The Use of Shredded Car Windscreen Waste as Reinforcement of Thermoplastic Composites for 3D (FDM) Printing,’ authored by Piotr Olesik, Mateusz Koziol, Daria Konik, and Jakub Jała, outlines their recent experimentation with shredded windscreen glass in FDM 3D printing.

In beginning their study, the researchers were able to obtain glass powder from ground windscreen glass waste to create a composite for 3D printing filament by adding low density polyethylene (LDPE). The powder still contained the PVB (polyvinyl butyral), however, which is a necessary component to safety glass as a binding resin that adds strength but also some degree of flexibility. By keeping it in the mix they were also able to eliminate the added expense of removal.”

Read more on this story here.

It’s an interesting concept that might not only be practical but also help to reduce waste from old windshields. 3D printing has seen all sorts of advacements over the last decade. Most notably is the progress made in the medical field as it pertains to 3D printed organs. It’s doubtful that you’ll see old car windshields used for printing out devices for medicine, however, there is certainly potential for other great things.

Speaking of great things, the team at IAS Auto Glass is always eager to help customers with their windshield repair or replacement. Call us at 952-797-4374 to schedule service. We also provide mobile service at no extra charge to area residents.